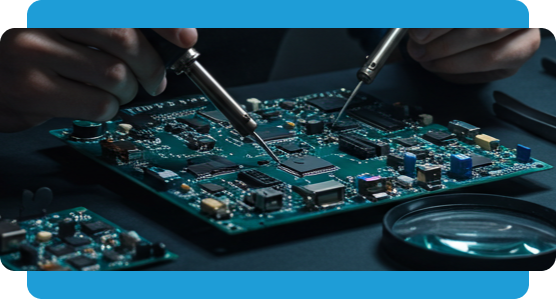

August Electronics provides full-service marine electronics manufacturing tailored to the unique demands of the maritime industry. From complex PCB assemblies and cable harnesses to complete box builds, we support the full lifecycle of your product with a collaborative, quality-first approach. Whether you’re building for commercial vessels, defense systems, offshore energy, or oceanographic research, our team understands the mission-critical nature of your product and what it takes to get it right the first time.

We specialize in low-to-mid volume, high-complexity builds where reliability is non-negotiable. Our in-house engineering support helps derisk designs before they reach the floor, while our ISO 9001 and ISO 13485-certified quality systems ensure every unit is built to spec. With secure domestic production and flexible long-term support, we’re the marine electronic equipment manufacturer trusted to deliver performance at sea, not just on paper.