Electronic Prototype Manufacturers

Your Partner for Production-Ready Prototypes

Bring your product idea to life with prototypes built to transition seamlessly into full production.

Your Partner for Production-Ready Prototypes

Bring your product idea to life with prototypes built to transition seamlessly into full production.

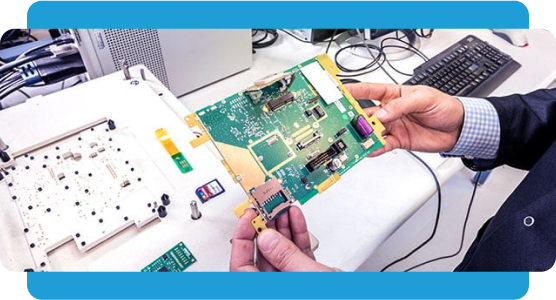

Every great product starts with a prototype. The real challenge is turning your concept into a tangible, manufacturable electronic product. As part of the New Product Introduction (NPI) process, we work alongside you to refine your product design, validate functionality, and ensure the hardware meets the highest standards for usability and manufacturability.

You bring your vision. We bring cutting-edge technologies and decades of expertise in manufacturing working electronic prototypes, from PCB design and testing to component selection. If you’re looking to create not just a prototype but a launch-ready product, we’re the partner for you.

OUR CAPABILITIES

Our state-of-the-art SMT lines deliver precision and efficiency, making even the most intricate electronic prototyping projects possible. These capabilities are ideal for prototypes requiring compact systems, ensuring high-quality circuit design and reliability at every step.

When durability and robust connections matter, our through-hole PCB assembly capabilities shine. This process is critical for hardware in demanding environments, such as industrial automation or renewable energy devices, ensuring each unit performs consistently in real-world applications.

Our 85,000 sq. ft. facility allows us to handle intricate system architecture, including box builds, custom cable assemblies, and high-density PCB assemblies. Whether your prototype involves complex PCB design or requires integrating mechanical and electronic components, our flexible manufacturing space and advanced tools allow us to adapt to specialized configurations, high-mix, and low-to-mid volume builds.

We take electronics prototyping further with comprehensive in-house testing. Our services include dielectric testing, functional testing, and environmental stress testing to validate that your prototype meets the highest performance standards and is ready for full-scale manufacture.

MANUFACTURING PROCESS

Prototyping begins after the initial electronic prototype design phase, where your product idea is developed and basic specifications are outlined. While this step typically happens before partnering with us, we’re always happy to collaborate with your engineering team to refine your design and prepare it for prototyping.

The assembly process involves advanced SMT and through-hole PCB assembly techniques to place components on your circuit board accurately. These methods ensure precision and reliability, building the foundation for a high-quality, scalable prototype.

We conduct thorough DFM and DFT reviews to assess manufacturability and scalability. Any issues identified are adjusted to ensure your prototype can be efficiently produced and tested at scale, reducing potential delays in the production phase.

Your prototype undergoes rigorous testing to ensure it meets design specifications, functionality, and durability requirements. This includes stress testing, environmental testing, and functional testing to validate that the prototype performs reliably under real-world conditions.

Using insights from testing, we refine the prototype by adjusting the design and materials. Additional prototype versions may be created as needed, ensuring the prototype meets all usability, scalability, and system architecture requirements.

Once the prototype is validated, it moves into the approval stage. Final adjustments are made to the design, and the manufacturing team prepares materials, workflows, and processes to ensure a seamless transition to full-scale manufacturing.

TESTIMONIALS

WHY AUGUST ELECTRONICS

With over 30 years in the industry, August leverages expertise in component selection, ensuring prototypes are cost-effective and compatible with long-term production plans.

We track every prototype through development, analyzing data to improve quality and efficiency. Built to IPC-A-610 Class 2 or 3 standards, our prototypes are reliable, functional, and production-ready.

With all services under one roof, we streamline your development process and reduce costs. From early stages to market, we help you scale efficiently and confidently.

Our 85,000 sq. ft. facility is equipped for rapid prototyping and advanced testing. By managing everything in-house, we ensure your prototype is precise, efficient, and ready for production.

Our rigorous testing strategies eliminate risks and ensure your product’s reliability. Every prototype undergoes dielectric testing, functional testing, and AQL inspections to verify safety and functionality.

RESOURCE LIBRARY

CONTACT US

Timelines vary based on project complexity and specific requirements. We work closely with each client to establish realistic timelines that align with their goals and ensure all necessary testing and quality checks are completed.

We specialize in small-batch prototyping designed to transition into volume production. While single-unit prototypes with no plans for scaling don’t align with our services, we’re the perfect partner for projects ready to evolve into mass production.

We encourage full collaboration throughout the prototyping process. From initial design reviews to iterative refinements, our project managers keep you informed and welcome your input at every stage to ensure the final prototype meets your vision and requirements.

We provide prototyping services as part of our New Product Introduction (NPI) process, supporting clients with high-quality electronic products designed to transition seamlessly into full production. Our services include Design for Manufacturability (DFM) and Design for Testing (DFT) reviews, SMT and through-hole PCB assembly, and custom box build assemblies.

Absolutely. Our prototyping services include DFM and DFT feedback to help optimize your electronic design for efficient and cost-effective production. This process minimizes issues in full-scale manufacturing, helping to save time and resources.

Yes, we offer support for strategic component sourcing, helping select cost-effective and high-quality components compatible with production at scale. Our extensive industry experience allows us to source materials effectively, ensuring consistency and availability for full production.

Our facility is equipped with advanced SMT and through-hole PCB assembly capabilities and tools for complex box builds and custom assemblies. With 85,000 square feet of flexible manufacturing space, we can manage diverse, large-scale projects across our cutting-edge equipment. This extensive space allows us to adapt quickly to unique assembly needs, support high-mix, low- to mid-volume builds, and handle projects requiring specialized configurations. We’re prepared to discuss and accommodate any unique requirements during the planning phase to ensure each project’s success.