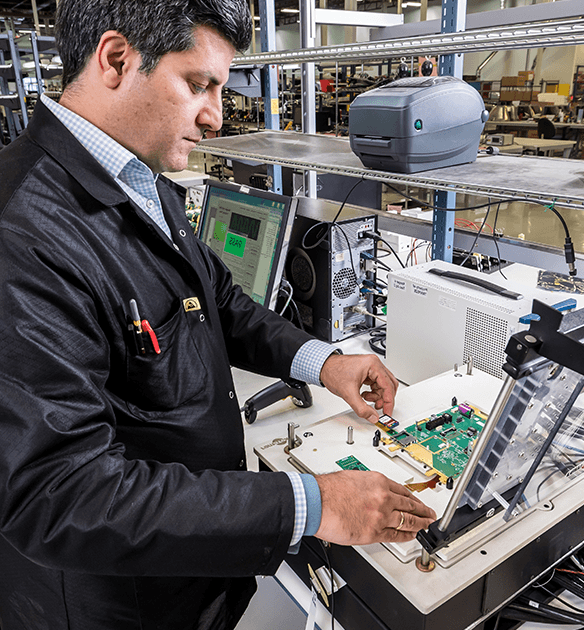

Quality delivered.

We have an extensive Quality Management System (QMS) that enables us to quickly identify non-conforming product, segregate it, and prevent its recurrence. Identifying and managing risk is a key component of our QMS, often enabling us to prevent issues before they get started. We have a long-standing track record of consistently meeting client expectations of quality, at the right cost to our clients.