Yes, design for manufacturing (DFM) can significantly reduce production costs and lead times. By optimizing designs for efficient production processes, DFM reduces material waste, minimizes manual assembly, and prevents manufacturing defects. Our team focuses on balancing performance with cost by identifying lower-cost alternatives for materials, components, and processes, ensuring quality is maintained while reducing production expenses.

Additionally, DFM helps mitigate supply chain risks. We often suggest alternative components, particularly when specified parts become obsolete or difficult to source. This approach keeps costs down and ensures more secure supply options.

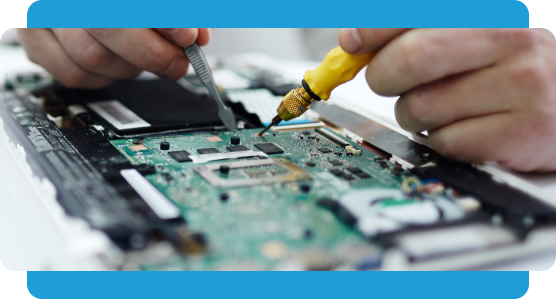

A key goal of DFM is to minimize manual labor in manufacturing by simplifying designs and incorporating automation-friendly features. This reduces labor costs and improves production efficiency, leading to higher product quality and consistency.