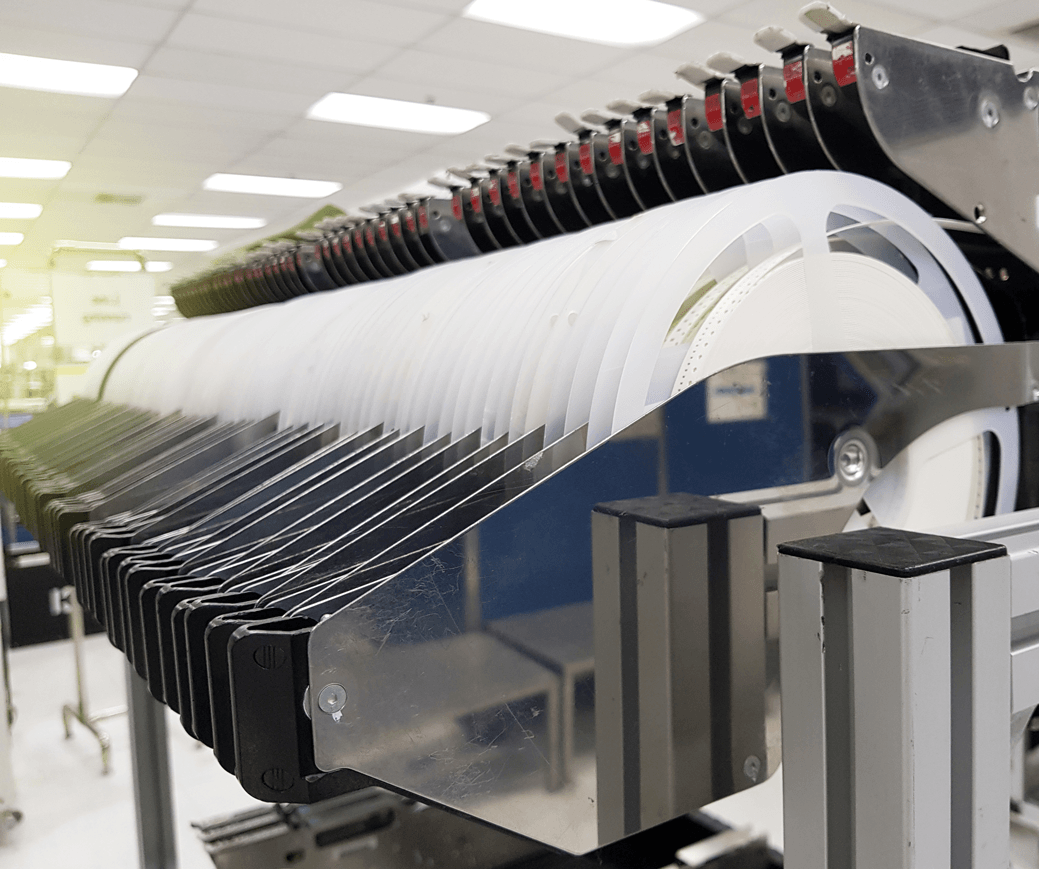

A smart supply chain that enhances manufacturing.

As your strategic partner for electronic manufacturing services (EMS), we understand the need for supply chain management (SCM).

Our engineering, procurement, supply chain and logistics teams are experts at identifying sourcing options tailored to your specific needs.

We supply a variety of products to diverse industries. This requires us to procure a wide portfolio of component types, from machined, die-cut, cast and formed metal products to high-end electronic components, plastics, brackets, wires, motors, power supplies and more.

We have long-standing, collaborative relationships with vetted suppliers in the global marketplace. This reduces our cost of acquisition and the supply chain complexity, while maintaining our commitment to quality and delivery timelines.

As an ISO certified manufacturer, we follow an industry recognized supplier evaluation process to partner and secure reputable suppliers. We continually evaluate and monitor their performance to limit non-conforming materials and components from entering our production floor.