What Is Electromechanical Assembly? The Key to Faster, Smarter Production

You may have the smartest, most innovative design in the world—but if it’s not assembled right, it’s just a pile of parts.

When electronics and mechanical systems don’t come together the right way, the whole product suffers. You get signal issues. Alignment problems. Thermal headaches. Field failures. And suddenly, that amazing idea doesn’t look so amazing anymore.

That’s why electromechanical assembly is a make-or-break capability. It’s where circuit boards, wire harnesses, sensors, and mechanical elements are brought together correctly—with reliability, repeatability, and long-term performance in mind.

Now, let’s be honest: electromechanical assembly isn’t new. It’s not flashy. But in a world where products are getting smaller, smarter, and more complex, how you handle that integration has never mattered more.

So, what exactly is electromechanical assembly—and why are smart manufacturers treating well-executed electromechanical assembly as a strategic advantage?

What is Electromechanical Assembly?

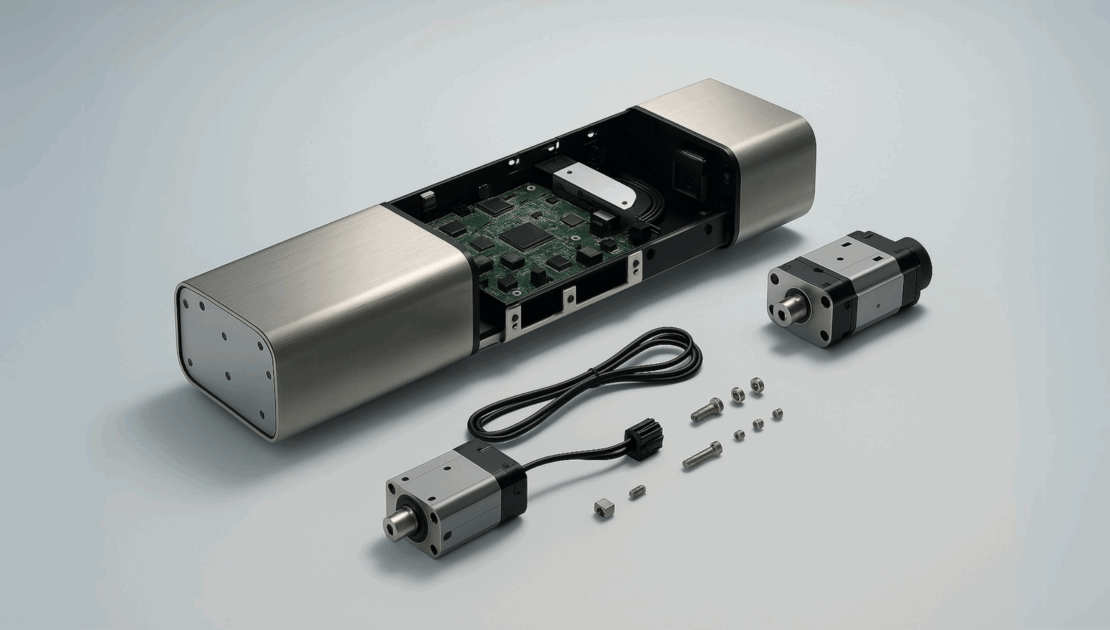

Electromechanical assembly is just what it sounds like: putting together systems with both electrical and mechanical parts. While printed circuit board assembly deals with electronic components, and mechanical manufacturing focuses on structural elements, electromechanical assembly is where these come together into one functioning product.

The process requires attention to several key areas:

- Signal paths: Making sure electrical signals can travel cleanly through the system

- Mechanical fit: Ensuring parts physically align and connect correctly

- Interface points: Creating reliable connections between different subsystems

- Environmental considerations: Building assemblies that can handle real-world conditions

Getting this right means understanding how electrical and mechanical systems affect each other. For instance, a connector placement that makes sense from a circuit board perspective might create problems when mechanical stress is applied during normal use. These issues only become obvious when you look at the whole system, not just the individual parts.

The Impact of High-Quality Electromechanical Assembly

Beyond its technical definition, proper electromechanical assembly offers practical benefits for manufacturers and customers.

Creates Products That Actually Work as Designed

The most innovative products blur the line between electrical and mechanical systems. Think about a medical diagnostic device: what matters is how well the touch interface, processing electronics, and sampling mechanism work together, not as individual components.

Effective electromechanical assembly ensures this seamless operation by:

- Creating consistent connection points between subsystems

- Maintaining proper alignment between sensors and mechanical elements

- Preventing electrical noise from compromising signal quality

- Ensuring repeatable performance across production runs

This integration is invisible to the end user, but it’s what separates exceptional products from just functional ones.

Streamlines Production

As products become more complex, assembly gets more challenging. A structured approach to electromechanical assembly helps by:

- Using modular designs that allow parallel work

- Creating standard interfaces that simplify testing

- Applying automation where it makes sense

- Maintaining clear documentation that anyone can follow

These efficiencies translate directly to the crucial advantages of faster time-to-market and more competitive pricing.

Makes Maintenance Easier

Products eventually need service or repairs. Smart electromechanical assembly makes this easier by:

- Organizing components in logical, accessible groups

- Creating service points that don’t require complete disassembly

- Implementing cable management that allows targeted component replacement

- Using standardized connectors that simplify diagnostics and repairs

For example, an industrial control panel designed with maintenance in mind might feature modular circuit boards that can be swapped out in minutes rather than hours, minimizing expensive downtime.

Works for Any Production Volume

Whether you’re making ten prototypes or ten thousand units, the same assembly principles apply. This consistency comes from:

- Documented procedures that ensure quality at any volume

- Reliable component sources that can scale with demand

- Testing approaches that work efficiently regardless of quantity

- Assembly methods that can transition from manual to automated as needed

This flexibility allows manufacturers to validate designs with limited production runs and then scale confidently when market demand grows—without facing manufacturing redesigns or quality setbacks.

Companies that excel at electromechanical assembly gain measurable advantages: faster product launches, fewer field failures, and lower warranty claims. These benefits compound over time, especially for medical device manufacturers facing FDA scrutiny or telecommunications providers where network downtime carries significant penalties. As products continue incorporating more sensor assemblies and electronic controls, mastering this integration becomes a key differentiator between those leading the pack and those struggling to keep up.

Core Types of Electromechanical Systems

Electromechanical assembly encompasses a broad spectrum of systems, each with specific requirements and applications. Understanding these core types helps identify the right manufacturing approach for your specific needs.

Sensor and Switch Assemblies

These systems detect external stimuli and turn them into electrical signals or control electrical flow based on mechanical inputs. They include:

- Pressure sensors that monitor fluid or gas levels in medical devices

- Position switches that detect mechanical movement in security systems

- Optical encoders that measure precise motion in robotic applications

- Temperature sensors that monitor critical equipment in industrial settings

The challenge with these common assemblies lies in maintaining calibration and accuracy while ensuring durability in their operating environment. Proper electromechanical assembly ensures consistent performance throughout the product lifecycle.

Box Build and System Assemblies

Complete functional units housed within enclosures represent the most comprehensive form of electromechanical assembly. Examples of these systems include:

- Network infrastructure equipment for telecommunications

- Patient monitoring devices for healthcare applications

- Process control systems for manufacturing environments

- Data acquisition systems for scientific and research applications

Box builds integrate multiple PCBs, power supplies, user interfaces, and external connection points into a cohesive system. The complexity comes from coordinating all these elements while maintaining quality.

Control Panels and Panel Assemblies

These interface-focused systems provide user control while housing complex electronics in structured, accessible layouts:

- Industrial control panels for production equipment

- Power distribution units for data centers

- Operator stations for machinery

- Building automation interfaces

Control panels require meticulous wiring organization, clear labelling, and an intuitive layout to ensure functionality and serviceability. Proper assembly techniques prevent signal interference or thermal buildup that could compromise performance.

Power Supply Assemblies

These convert and regulate electrical power for sensitive electronics:

- AC/DC power converters for medical equipment

- Battery management systems for portable devices

- Uninterruptible power supplies for critical infrastructure

- Custom power distribution systems for specialized applications

Power supply assemblies demand precision assembly to ensure electrical safety, thermal management, and reliability under varying load conditions. Integrating high-voltage components with control electronics requires specialized expertise to prevent hazards and ensure long-term performance.

Wire Harness and Cable Assemblies

These connection systems create the pathways for power and signals throughout the device:

- Custom cable assemblies with specific terminations

- Complex wire harnesses that organize multiple connections

- High-speed data cables for telecommunications equipment

- Specialized medical-grade cabling for healthcare devices

Proper cable and harness assembly prevents signal degradation, ensures secure connections, and maintains clear, organized pathways that support long-term reliability.

Common Electromechanical Assembly Techniques

Behind every successful electromechanical system lies a set of specialized PCB manufacturing and assembly techniques. These methods form the foundation for reliable integration between electrical and mechanical components.

Surface Mounting

Surface-mount technology (SMT) has become the standard for modern PCB assembly within electromechanical systems due to its numerous advantages:

- Miniaturization: Enables much higher component density than through-hole techniques

- Automated efficiency: Utilizes high-speed pick-and-place machines for consistent placement

- Superior performance: Reduces lead lengths to minimize signal interference in sensitive applications

- Mechanical advantages: Creates lighter, thinner assemblies that integrate more easily into compact enclosures

Surface mounting allows for compact control boards that fit within mechanical constraints while providing a reliable foundation.

Through-Hole Mounting

While surface mounting dominates modern electronics, through-hole technology remains essential for specific electromechanical applications:

- Power components: Handles higher current and thermal loads at critical power connection points

- Mechanical stress points: Provides superior physical strength where boards connect to chassis points

- User interface elements: Offers durability for essential components like connectors and switch panels that experience frequent mechanical interaction

- Specialized components: Accommodates parts only available in through-hole packages

These stronger connections help withstand vibration, temperature changes, and mechanical forces that might damage surface-mount connections.

Soldering

The soldering process creates connections between components and circuit boards, with several specialized techniques employed in electromechanical assembly:

- Reflow soldering: Uses precisely controlled heat to melt pre-applied solder paste, creating consistent connections across surface-mount components

- Wave soldering: Passes boards over a molten solder wave to create reliable through-hole connections

- Selective soldering: Targets specific areas with programmable nozzles, ideal for mixed-technology boards

- Hand soldering: Provides precision for delicate connections or prototype modifications

The quality of these connections directly affects reliability, especially when products experience mechanical stress or temperature changes.

Circuit Layout

The physical arrangement of components and traces on a PCB greatly influences an electromechanical assembly’s performance and reliability:

- Signal integrity planning: Minimizes interference between high-speed data lines and electrical circuits

- Thermal management: Strategically places heat-generating components to prevent hotspots

- Mechanical integration: Aligns mounting points, connectors, and interfaces with the mechanical assembly

- Serviceability considerations: Groups related components logically for easier troubleshooting and repair

Effective PCB layout for electromechanical systems requires close collaboration between electronic and mechanical designers. A board that functions perfectly on the bench may fail when mounted in its final position if mechanical stresses, thermal conditions, or electromagnetic interference aren’t properly considered during layout.

Quality Control in Electromechanical Assembly

Quality assurance in electromechanical assembly combines rigorous inspection, comprehensive testing, and adherence to industry standards to ensure reliable, consistent products.

Inspection and Testing

The most effective quality assurance programs implement multi-level verification:

- Automated Inspection using 2D and 3D solder paste inspection (SPI) and Automated Optical Inspection (AOI) catches defects early in the process. X-ray inspection examines hidden solder joints that are otherwise impossible to verify.

- First Article Approval validates the first production unit against all specifications before proceeding with full production, preventing systemic issues from affecting entire runs.

- Comprehensive Testing including In-Circuit Testing (ICT) with both powered digital and unpowered analog verification, functional testing with software-driven validation, and dielectric testing for electrical safety compliance.

These verification steps create multiple opportunities to catch and correct issues before they reach the field, dramatically reducing failure rates and warranty claims.

Standards and Traceability

Formal certifications and traceability systems provide structure to quality processes:

- Industry Certifications such as ISO 9001:2015 and ISO 13485:2016 and compliance with IPC-A-610 standards demonstrate a commitment to consistent quality processes.

- Safety Approvals including UL, CSA, and ETL standards, ensure products meet rigorous safety requirements.

- Component Tracking using barcode systems provides complete traceability throughout manufacturing, allowing rapid response to any issues.

Leading manufacturers maintain IPC-certified staff, including specialized certifications like IPC 7711/7721 for rework and repair, ensuring quality standards are properly implemented at every stage of production.

Selecting the Right Manufacturing Partner

Successful electromechanical assemblies require specialized expertise across multiple disciplines. When evaluating manufacturing partners for your next project, several critical factors can determine whether your product reaches the market on time, within budget, and with the reliability your customers demand:

- End-to-End Integration Expertise: Look for a partner who understands your product’s electrical and mechanical aspects, not just isolated components.

- Quality Certifications: Verify that the manufacturer holds relevant certifications for your industry, particularly ISO 9001, ISO 13485 for medical devices, and IPC standards.

- Traceability Systems: Complete component tracking throughout the manufacturing process provides accountability and facilitates rapid resolution if issues arise.

- Scalable Capacity: Ensure your partner can handle your initial production needs and grow with your success without compromising quality.

The August Electronics Advantage

At August Electronics, we’ve spent over 30 years perfecting our approach to electromechanical assembly, with particular expertise in medical devices, industrial automation, telecommunications, and other complex electronic systems.

Our 85,000 sq. ft. ISO 9001:2015 and ISO 13485:2016 certified manufacturing facility provides the foundation for our comprehensive electromechanical assembly services, including:

- Complete PCB Assembly: Utilizing advanced SMT and through-hole capabilities with rigorous inspection throughout the process

- Full Box Build Integration: Transforming circuit boards, cables, and mechanical components into finished, market-ready products

- Comprehensive Testing: From automated inspection systems to customized functional testing that verifies real-world performance

- Supply Chain Management: Sourcing components from trusted suppliers and managing inventory to prevent production delays

The August team understands the critical nature of electromechanical integration—where your product’s success depends on how seamlessly electronic and mechanical components work together. We’ve built our processes around creating this harmony, ensuring that every product that leaves our facility meets the highest standards of quality and reliability.Ready to explore how our electromechanical assembly expertise can support your next project? Contact us today to discuss your specific requirements.