How Much Does It Cost to Manufacture Electronics?

How Much Does It Cost to Manufacture Electronics?

When people ask how much it costs to manufacture electronics, the most honest answer is: It depends.

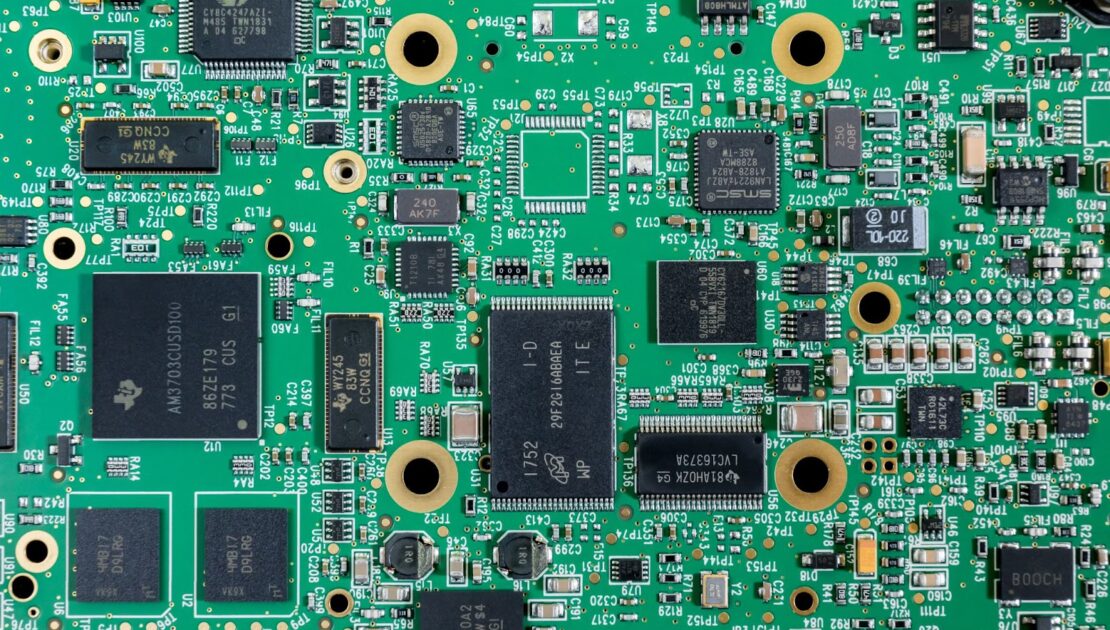

The cost depends on what’s being made, its complexity, and what it takes to get it ready for market. A basic printed circuit board assembled in volume can cost only a few dollars per unit. At the same time, a complex, regulated device with advanced components and multiple assemblies can run into the hundreds or even thousands per unit.

Electronic manufacturing costs are the sum of many moving parts: the components you choose, the volumes you build, the level of testing required, and the compliance standards you need to meet. Each factor carries its own weight, and that balance shifts depending on your product and industry.

In this article, we’ll break down the five core pillars affecting the cost of electronic products, examine the design choices that most influence price, and highlight the less obvious costs that can catch teams off guard. By the end, you’ll have a clear framework for understanding what really goes into the cost of manufacturing electronics.

What Drives the Cost of Electronics Manufacturing

These are the baseline costs every project faces. No matter the product, five core pillars consistently shape the total cost of electronics manufacturing. The weight of each shifts depending on your product type, industry, and stage of development, but all must be considered from the start of the manufacturing process.

Materials and Components

The bill of materials (BOM) usually accounts for the largest share of production costs. Some passives may be inexpensive, while high-performance electronic components like semiconductors quickly raise costs. Availability also plays a role—scarce or end-of-life critical components can inflate actual costs and create supply risks.

Choosing stable, widely available parts creates cost-saving opportunities.

Volume and Scale

The more units you build, the lower your cost per unit. Prototypes and short runs carry higher overhead because setup, line changeovers, and minimum order quantities aren’t spread out.

High-volume mass production spreads those costs across tens of thousands of builds, improving cost efficiency.

Labor and Expertise

Not every step of the manufacturing process can be automated. Builds requiring hand soldering, box build integration, or compliance with IPC Class 3 standards demand skilled labor. That expertise adds to labor costs, but also reduces rework and keeps the assembly process on schedule.

Experienced engineering support also shortens the path from prototype to production, helping new products reach the market faster.

Testing and Quality

Every product must be tested, but the type and depth of testing vary. Functional checks, in-circuit testing, automated optical inspection (AOI), and environmental stress testing all improve product quality but add additional costs. The right mix balances reliability with budget.

Effective testing also protects yield, and high first-pass yield is one of the most reliable ways to avoid hidden costs tied to rework, scrap, and warranty issues.

Compliance and Traceability

Products in regulated product categories—medical, aerospace, automotive—require added documentation, certifications, and full traceability. Serialization and audit-ready records are often mandatory, raising overhead expenses beyond what’s needed for commercial builds.

Why Quotes Often Feel Higher Than Expected

Even after you understand the main cost pillars, the first quote can still come as a surprise, often higher than teams anticipate. Expectations are often shaped by past experience, especially if you’ve worked with offshore suppliers. Overseas builds typically benefit from lower labor costs, larger manufacturing volumes, and stronger purchasing leverage, all of which push the unit price down.

Domestic manufacturing reflects different realities: fair wages, tighter compliance standards, and more rigorous documentation. While this can raise the unit cost, it also brings important advantages like faster communication with your build team, clearer visibility into supply chain challenges, stronger control over product quality, and a partner who is invested in your long-term success rather than just the next transaction.

Manufacturing and Compliance Requirements That Add Cost

Beyond the core pillars, certain situational add-ons depend on the market and industry. Not every product needs them, but when they apply, they can significantly increase the final cost of manufacturing.

Material and Regulatory Compliance

Standards like RoHS, UL, and CE ensure safety and reliability but add development cost for compliant sourcing, documentation, and certification testing.

Specialized Manufacturing Processes

Some assemblies demand extra processes for durability or performance, such as:

- Conformal coating, potting, or encapsulation for harsh environments

- Class 3 soldering for high-reliability assemblies

- Full box build and system integration

Each increases labor costs and extends the assembly lines, though they’re often necessary to protect the product’s functionality and maintain product quality.

Traceability and Documentation

In regulated industries, every component may need to be logged back to its origin. Serialization, audit-ready records, and detailed documentation add to actual costs, even if they don’t directly affect the quoted cost per unit.

Industry Certifications

Some markets carry strict requirements:

- Medical: ISO 13485, Health Canada, FDA — strict documentation, process validation, and full traceability

- Automotive: Advanced statistical process control and quality management

- Aerospace and defense: Secure processes, extensive oversight, and even background checks for workers

These certifications ensure compliance and market access, but introduce major manufacturing cost factors that must be budgeted for early. They can also extend project timelines, so teams should consider time-to-market alongside the certification requirements themselves.

The Hidden Costs of Electronics Manufacturing

Even after you’ve accounted for the pillars and situational requirements, there are still overlooked areas and line items that don’t show up until later in the build. These are the costs that catch teams by surprise.

Design and Process Oversights

- Testing requirements: Skipping DFT features like test points adds fixture costs and slows throughput.

- Design complexity: Fine-pitch BGAs, high-layer-count PCBs, and mixed technologies extend setup time and inspection.

- Volume scaling: Prototypes and low runs carry a higher cost per unit because NRE and setup costs aren’t spread out.

Supply Chain and Compliance Realities

- Component risks: Purchase price variance (PPV), end-of-life parts, and long lead times can drive sudden spikes in actual costs.

- Surprise documentation needs: Serialization, audit-ready records, and certification requirements can bring overhead expenses that weren’t part of the initial quote.

- Logistics: Freight, tariffs, shipping, inventory, and warehousing costs are often not factored into the initial quote.

Quote-Related Line Items

- NRE charges: Tooling, stencils, test fixtures, and programming often appear as one-time fees.

- Change orders: Design or BOM changes mid-stream cause stoppages, reprogramming, and rework, all of which raise the final cost.

- Certification testing: Meeting requirements from the Federal Communications Commission or European Union can add testing fees that weren’t part of the original estimate.

Together, these factors represent the difference between an attractive sales price on paper and the real costs of bringing a product to market. Planning for them early ensures your profit margins and go-to-market timeline aren’t derailed later.

How to Compare Quotes the Right Way

When companies shop for an electronics manufacturing partner, it’s tempting to focus on the bottom line. But two quotes with the same unit cost can hide very different assumptions. The cheapest option on paper isn’t always the most cost-effective in practice.

Look Beyond the Numbers

Some providers quote only the assembly cost, while others include testing, compliance, or tooling charges. Before comparing, normalize the scope so you’re reviewing apples to apples.

Ask About Assumptions

Every estimate is based on specific inputs—lead times, manufacturing volume, approved alternates for key components, and sourcing strategies. If those assumptions aren’t clear, ask for clarification. Without it, you may face unexpected additional costs down the line.

Consider Total Cost of Ownership

A slightly higher cost per unit can save money overall if it means fewer delays, higher yields, or less risk of rework. The right question isn’t “Which is cheapest?” but “Which quote reduces risk and protects profit margins?”

Evaluate Communication and Transparency

A strong partner explains not just the number, but the reasoning behind it. Look for suppliers who walk you through risks, supply chain challenges, and potential cost-saving opportunities. Responsiveness and transparency are as important as the quote itself.

The best manufacturing relationships feel like partnerships—shared forecasting, clear communication, and proactive planning all help keep costs predictable and profit margins protected.

Why Time-to-Market Matters as Much as Price

Price is only one side of the equation. Delays in reaching the market can be just as costly as the build itself. Missing a seasonal launch window, slipping a regulatory deadline, or falling behind a competitor often means lost revenue that dwarfs any savings squeezed from the BOM.

A manufacturer’s ability to support New Product Introduction (NPI) is critical. Fast DFM feedback keeps revisions from dragging on, and smooth ramp-up processes help move from prototype to production without roadblocks. The longer design iterations stretch, the more development costs rise, and the greater the risk that your product misses its window.

Planning for time-to-market early ensures the entire manufacturing process is set up to move quickly without sacrificing product quality. In practice, this balance is one of the strongest cost-saving opportunities available. A slightly higher production cost can often deliver a far better return if it protects your launch timeline and long-term growth.

Choosing the Right Partner

As we’ve seen, managing electronic manufacturing costs is a complex process with many moving parts. There’s the cost of all the electronic components, then labor costs, inventory costs, packaging costs, and shipping costs… Why not work with a partner who can guide you through the trade-offs, keep risks visible, and help you balance cost, quality, and time to market?

The best manufacturing relationships feel like partnerships. Shared forecasting, clear communication, and proactive planning help keep costs predictable and profit margins protected. That’s the role we aim to fill at August Electronics.

We don’t just provide a quote and leave you to figure out the rest. Our team walks through the cost factors with you, explains the assumptions behind the numbers, and helps identify cost-saving opportunities before they become unwelcome surprises. From materials sourcing and PCB design feedback to testing, certifications, and final product assembly, we act as an extension of your team to keep every dollar working toward the right outcome.

If you’re planning your next build, start by asking what it costs and what’s driving that cost. With the right electronic manufacturing company as a partner, you’ll have a clear view of the real costs, the trade-offs, and the path to market that protects both product quality and your long-term growth.

Don’t just chase the lowest quote. With August Electronics, you get a manufacturing partner focused on yield, quality, and predictable costs so your new electronic hardware product succeeds long after launch.